Professor of Solid and Structural Mechanics

Powder Compaction

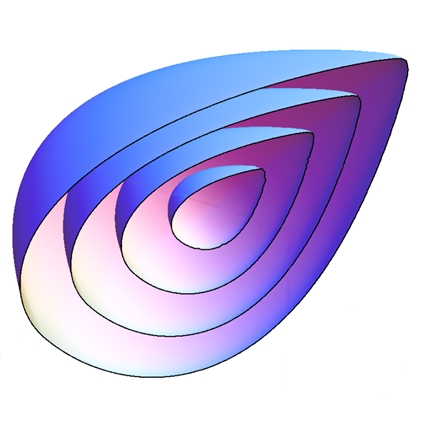

Cold powder compaction is a process in which granular materials are made cohesive through mechanical densification. Subsequent sintering usually completes the treatment and yields the desired mechanical properties of the final piece. Since this process permits an efficient production of parts ranging widely in size and shape to close tolerances, there is an evident related industrial interest, involving metallurgical and pharmaceutical applications and forming of traditional (e.g. ceramic tiles and porcelain products) and structural (e.g. chip carriers, spark plugs, cutting tools) ceramics.A crucial step in the above technique is the production of green bodies (i.e. the solids obtained after cold forming of ceramic powders) possessing enough cohesion to remain intact after mold ejection, being essentially free of macro defects, and handleable without failure in the subsequent treatments. This is not an easy task and indeed defects of various types are always present in the greens, negatively affecting local shrinkage during sintering. In particular, defects can be caused by the densification process, which may involve highly inhomogeneous strain fields, or by mold ejection.

We have formulated, developed and implemented a new elastoplastic phenomenological model which is capable of describing the deformation and consequent gain in cohesion of granular ceramic materials subject to mechanical loading.

The difficulty in the modelling of the process of mechanical compaction is that it requires the description of the transition from a granular to a dense or even a fully dense state. Since granular materials are characterized by mechanical properties much different from those typical of dense solids, the constitutive modelling must describe a transition between two distinctly different states of a material.

Related papers:

- S. Stupkiewicz, A. Piccolroaz, D. Bigoni,

Finite-strain formulation and FE implementation of a constitutive model for powder compaction.

Computer Methods in Applied Mechanics and Engineering, 2015, 283, 856-880.

[arXiv version] - S. Stupkiewicz, R. Denzer, A. Piccolroaz and D. Bigoni

Implicit yield function formulation for granular and rock-like materials.

Computational Mechanics , 2014, 54, 1163-1173. - F. Bosi, A. Piccolroaz, M. Gei, F. Dal Corso, A. Cocquio and D. Bigoni

Experimental investigation of the elastoplastic response of

aluminum silicate spray dried powder during cold compaction.

Journal of the European Ceramic Society, 2014, 34, 2633-2642. - M. Penasa, A. Piccolroaz, L. Argani and D. Bigoni

Integration algorithms of elastoplasticity for ceramic powder compaction.

Journal of the European Ceramic Society, 2014, 34, 2775-2788.

[arXiv version] - S. Stupkiewicz, A. Piccolroaz, and D. Bigoni

Elastoplastic coupling to model cold ceramic powder compaction.

Journal of the European Ceramic Society, 2014, 34, 2839-2848.

[arXiv version] - D. Bigoni, Nonlinear Solid Mechanics Bifurcation Theory and Material Instability. Cambridge University Press, 2012, ISBN:9781107025417.

- D. Bigoni, Selected Mechanical Problems in Structural Ceramics. AMAS Lecture Notes No. 3, Institute of Fundamental Technological Research, Warsaw, ISSN 1642-0578, 2002.

- A. Piccolroaz, D. Bigoni and A. Gajo, An

elastoplastic framework for granular materials

becoming cohesive through mechanical densification. Part I - small strain formulation.

European Journal of Mechanics A: Solids, 2006, 25, 334-357. - A. Piccolroaz, D. Bigoni and A. Gajo, An elastoplastic

framework for granular materials

becoming cohesive through mechanical densification. Part II - the formulation of elastoplastic

coupling at large strain.

European Journal of Mechanics A: Solids, 2006, 25, 358-369. - D. Bigoni and A. Piccolroaz, Yield criteria for

quasibrittle and frictional materials.

International Journal of Solids and Structures, 2004, 41(11-12), 2855-2878. - A. Piccolroaz, A. Gajo and D. Bigoni, Cold compaction of ceramic powders.

Materials Engineering, 2003, 14 (2), 157-169.

Free software

Feel free to use the notebook and the subroutines for your work provided the source, i.e. "S. Stupkiewicz, R. Denzer, A. Piccolroaz and D. Bigoni (2014) Implicit yield function formulation for granular and rock-like materials. Computational Mechanics, DOI 10.1007/s00466-014-1047-8" is adequately cited.

|

BP_yield_function.nb BP_yield_function.pdf |

Fortran Mathematica Matlab |

Back to main page